Postdoctoral Fellow - Nanotechnology

Northwestern University - 2013

Jeremiah Gassensmith

Professor – Chemistry & Biochemistry

Affiliate Faculty - Bioengineering

Professional Preparation

Ph.D. - Chemistry

University of Notre Dame - 2009

University of Notre Dame - 2009

B.S. (Hons) - Chemistry

Indiana University - 2003

Indiana University - 2003

Research Areas

Nanomedicine

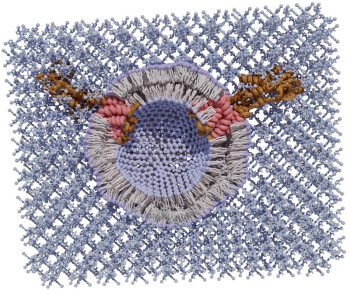

We use well-defined nano- and micro-porous crystalline materials that nucleate and grow rapidly on protein surfaces to create implantable or injectable composites for long-term protein delivery.Vaccines have saved many lives, but they are by no means perfect. They require constant refrigeration and may require multiple injections before exerting their therapeutic effect. Both these conditions significantly increase the cost of vaccines and inhibit access to these lifesaving medicines in developing nations. We have found that we can grow polycrystalline shells of a metal-organic framework (MOF) called Zeolitic Imidazolate Frameworks-8 (ZIF-8) on nearly any protein's surface. Furthermore, in these shells, the protein is thermally stabilized. The ZIF framework prevents the protein from moving, which inhibits its denaturation. We have found that ZIF-8 can dissolve in tissue and serum, causing the entrapped protein to be released. We have further found that subcutaneous implantation of ZIF-encapsulated protein results in the release of the protein with no apparent burst release. We have discovered an adjuvant effect in the case of vaccine-like therapeutics, which significantly amplifies the vaccine's efficacy. We aim to translate this technology to create “room temperature stable” and “single dose” vaccines that do not require follow-up booster shots. These could ultimately lead to greater patient compliance and, thus, much broader protection against dangerous pathogens for society. (Angew. Chem. Int. Ed. 2016, ACS Nano 2018, Nature Comms. 2021, ACS Nano2021, JACS 2022, Chem Sci 2022, PNAS 2023, Chem Sci 2023, Nat Rev Mat 2023, Chem Sci 2024, Chem Rev 2024)

Stimuli Responsive Behavior

Virus-like particles (VLPs) are engineered, tightly organized, self-assembled protein nanoparticles derived from viruses. Unlike viruses, however, they lack a genome and are incapable of infecting cells. Still, they retain the stability and resilience of their native protein against heat and solvent, making them tough proteins and ideal nanoparticles for developing into “smart” therapeutics. We are interested in modifying VLPs with organic or inorganic ligands that, when acted upon by light or heat, cause changes in how the protein behaves. In particular, we are interested in attaching photothermal antennae, which convert light into heat, to change or unfold proteins to release small-molecule drugs in highly localized places. We are also interested in using light and heat to alter the overall surface charge of these proteins. We have found that installing small organic molecules can change how well our cells take up VLPs. (Small 2016, JACS 2017, JACS 2021, JACS 2021, PNAS 2021,ACS Nano 2023)Molecular Imaging

Gadolinium-based contrast agents have dominated clinical contrast-enhanced MRI for decades. Gadolinium is a great metal for T1-enhanced contrast, but it has drawbacks. In particular, Gd is toxic to a non-negligible number of patients. More alarmingly, decades of use have resulted in the accumulation of Gd in watersheds, aquatic life, and soils in urban areas from patients excreting it following imaging. We are developing an alternative to Gd based on paramagnetic organic radicals, typically weak contrast agents easily reduced to diamagnetic radicals in vivo. We have developed a method to overcome these obstacles by attaching an organic radical contrast agent (ORCA) onto a large macromolecule, the Tobacco Mosaic Virus (TMV), which increases its contrast by an order of magnitude. We use a supramolecular shielding strategy using a cucurbituril macrocycle to protect the radical species from reduction while allowing interaction with water molecules. The resulting supramolecular/macromolecular organic radical contrast agent (SMORCA) is a persistent and bright T1 agent for in vivo imaging. (Mol. Pharm. 2018, Chem. Sci. 2020, J. Phys. Chem. B 2024)Publications

Optimization of Immunogenic Cell Death in Triple-Negative Breast Cancer with Virus-Like Particle-Based Photothermal Therapy 2025 - Other

Dually functionalized dendrimer for stimuli-responsive release of active ingredients into the skin 2025 - Journal Article

Fluorescent molecular probe for in vivo and in vitro targeting and imaging of an intracellular bacterial infection 2025 - Journal Article

Optimization of Immunogenic Cell Death in Triple-Negative Breast Cancer with Virus-like Particle-Based Photothermal Therapy 2025 - Journal Article

Metal-Organic Frameworks for Single-Dose Engineered Enzyme-Based Prophylaxis and Treatment of Organophosphate Poisoning 2025 - Other

Fluorescent molecular probe for in vivo targeting and live cell imaging of intracellular pathogenic E. coli 2025 - Other

Awards

Alexander von Humboldt Fellow - Humboldt Foundation [2024]

Fellow of the Royal Society of Chemistry - The Royal Society of Chemistry [2022]

President's Teaching Award - University of Texas at Dallas [2021]

Career Award - National Science Foundation [2017]

ACS PRF Doctoral New Investigator Award - The American Chemical Society [2016]

Faculty Teaching Award - School of Natural Sciences & Mathematics [2015]

Appointments

Affiliated Faculty—Advanced Imaging Research Center

UT Southwestern [2017–Present]

UT Southwestern [2017–Present]

Affiliate Faculty—Department of Biomedical Engineering

UT Dallas [2017–Present]

UT Dallas [2017–Present]

Associate Member—Simmons Comprehensive Cancer Center

UT Southwestern [2017–Present]

UT Southwestern [2017–Present]

News Articles

The Science of BBQ: A ‘Complicated Circus of Chemicals’

Cooking the perfect brisket is a lot like conducting a science experiment. And Dr. Jeremiah Gassensmith should know — he’s both a chemist and backyard barbecue chef.

Cooking the perfect brisket is a lot like conducting a science experiment. And Dr. Jeremiah Gassensmith should know — he’s both a chemist and backyard barbecue chef.The challenge is to apply just the right amount of heat and at the right speed to melt proteins called collagen in the meat to transform a tough, muscular cut of beef into a classic Texas delicacy, said Gassensmith, associate professor of chemistry and biochemistry at The University of Texas at Dallas.

Scared of needles? A puff of gas could one day deliver your vaccine

Yalini Wijesundara stared at the air gun sitting in her lab.

Yalini Wijesundara stared at the air gun sitting in her lab.Her lab director, Jeremiah Gassensmith, had built it in a spur of pandemic-induced boredom, shooting table salt around his home office. Once lockdown ended, he brought it to his biochemistry lab and asked Wijesundara to find a research purpose for it.

Wijesundara, then a first-year graduate student at the University of Texas at Dallas, had just moved to Texas from Sri Lanka. She felt like a fish out of water, still figuring out how the lab worked. Take your time, Gassensmith told her. You’ll figure it out.

Two years later, Wijesundara cracked the code. She brought new life to Gassensmith’s old air gun, creating a system to deliver vaccines with a puff of gas. It’s less painful than traditional needle vaccines, Wijesundara said, comparable to being hit by a Nerf bullet. The research was published in the journal Chemical Science last year.

Lipid Research May Help Solve COVID-19 Vaccine Challenges

New research by University of Texas at Dallas scientists could help solve a major challenge in the deployment of certain COVID-19 vaccines worldwide — the need for the vaccines to be kept at below-freezing temperatures during transport and storage.

New research by University of Texas at Dallas scientists could help solve a major challenge in the deployment of certain COVID-19 vaccines worldwide — the need for the vaccines to be kept at below-freezing temperatures during transport and storage.In a study published online April 13 in Nature Communications, the researchers demonstrate a new, inexpensive technique that generates crystalline exoskeletons around delicate liposomes and other lipid nanoparticles and stabilizes them at room temperature for an extended period — up to two months — in their proof-of-concept experiments.

The Moderna and Pfizer/BioNTech COVID-19 vaccines use lipid nanoparticles — basically spheres of fat molecules — to protect and deliver the messenger RNA that generates a vaccine recipient’s immune response to the SARS-CoV-2 virus.

Researchers Brighten Path for Creating New Type of MRI Contrast Agent

University of Texas at Dallas researchers are breathing new life into an old MRI contrast agent by attaching it to a plant virus and wrapping it in a protective chemical cage.

University of Texas at Dallas researchers are breathing new life into an old MRI contrast agent by attaching it to a plant virus and wrapping it in a protective chemical cage.The novel strategy is aimed at developing a completely organic and biodegradable compound that would eliminate the need to use heavy metals such as gadolinium in contrast agents, said Dr. Jeremiah Gassensmith, associate professor of chemistry and biochemistry in the School of Natural Sciences and Mathematics and corresponding author of a study published Feb. 5 in the journal Chemical Science, a publication of the Royal Society of Chemistry.

UT Dallas Scientists Study the Powers of Tiny Crystals

When it comes to the way scientists react to their discoveries, “That’s interesting” falls somewhere between “Eureka!” and “Uh-oh.”

When it comes to the way scientists react to their discoveries, “That’s interesting” falls somewhere between “Eureka!” and “Uh-oh.”“Interesting” is just what Dr. Jeremiah Gassensmith and his graduate student Madushani Dharmarwardana thought when they noticed unusual behavior in a sample of crystals they were working with in Gassensmith’s chemistry lab at The University of Texas at Dallas.

As part of her doctoral research, Dharmarwardana was investigating how the material, from a family of organic semiconducting materials called naphthalene diimides, changes color from orange to yellow as it is heated.

Affiliations

Associate Editor Chemical Engineering Journal

2023/03Handling articles on bioengineering, chemical reaction engineering, and novel materials